adAM 3D printer - Industrial serial production 2.0

Multifunctional machine tools

Advanced Additive Manufacturing - adAM -

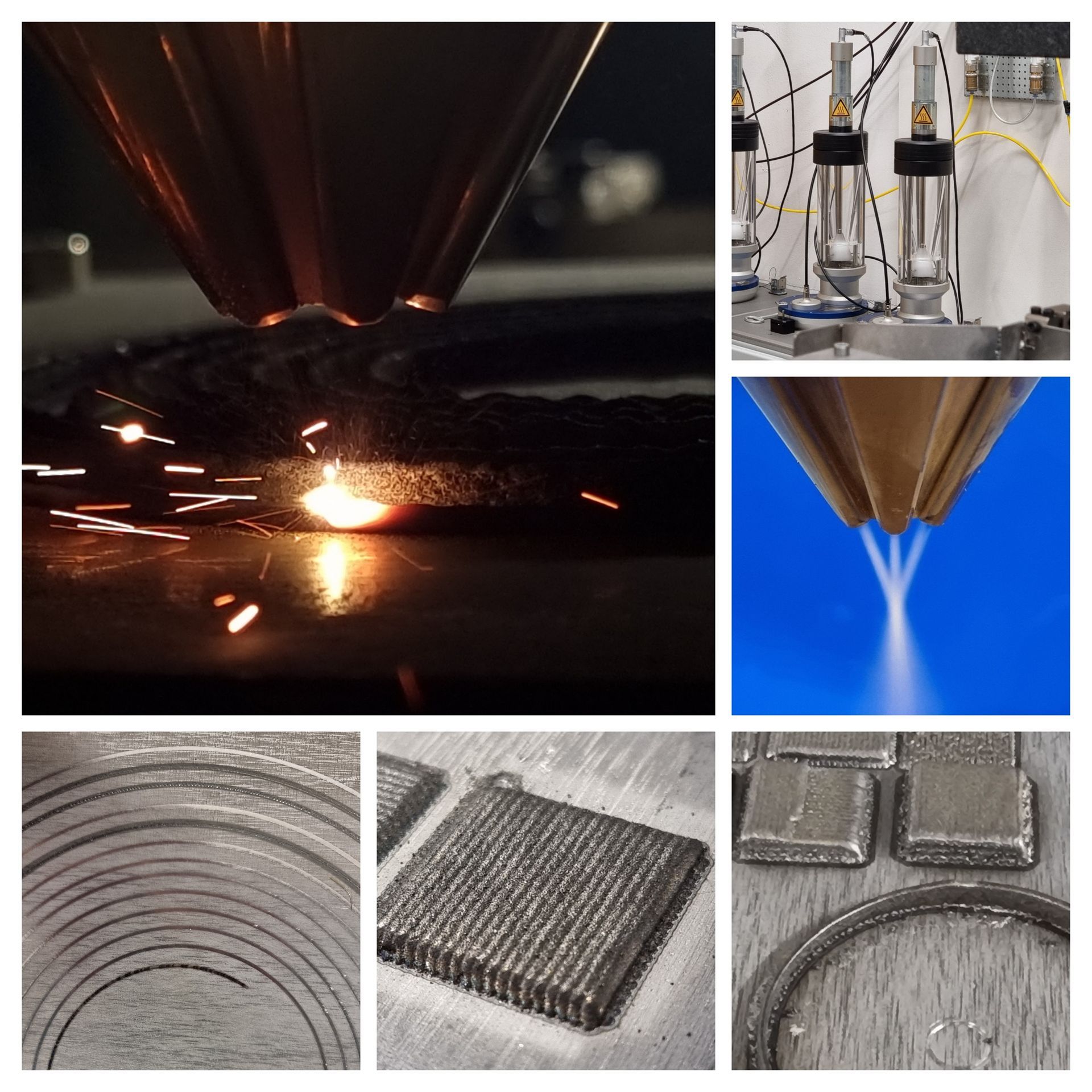

ODeCon engineering GmbH stands for groundbreaking developments in the field of additive manufacturing. With our adAM series, we offer state-of-the-art 5-axis CNC machine tools that are specifically optimized for laser-based processes such as high-speed laser cladding (EHLA). The machine concept provides for the integration of upstream and downstream processes, and we therefore speak of universal hybrid machine tools

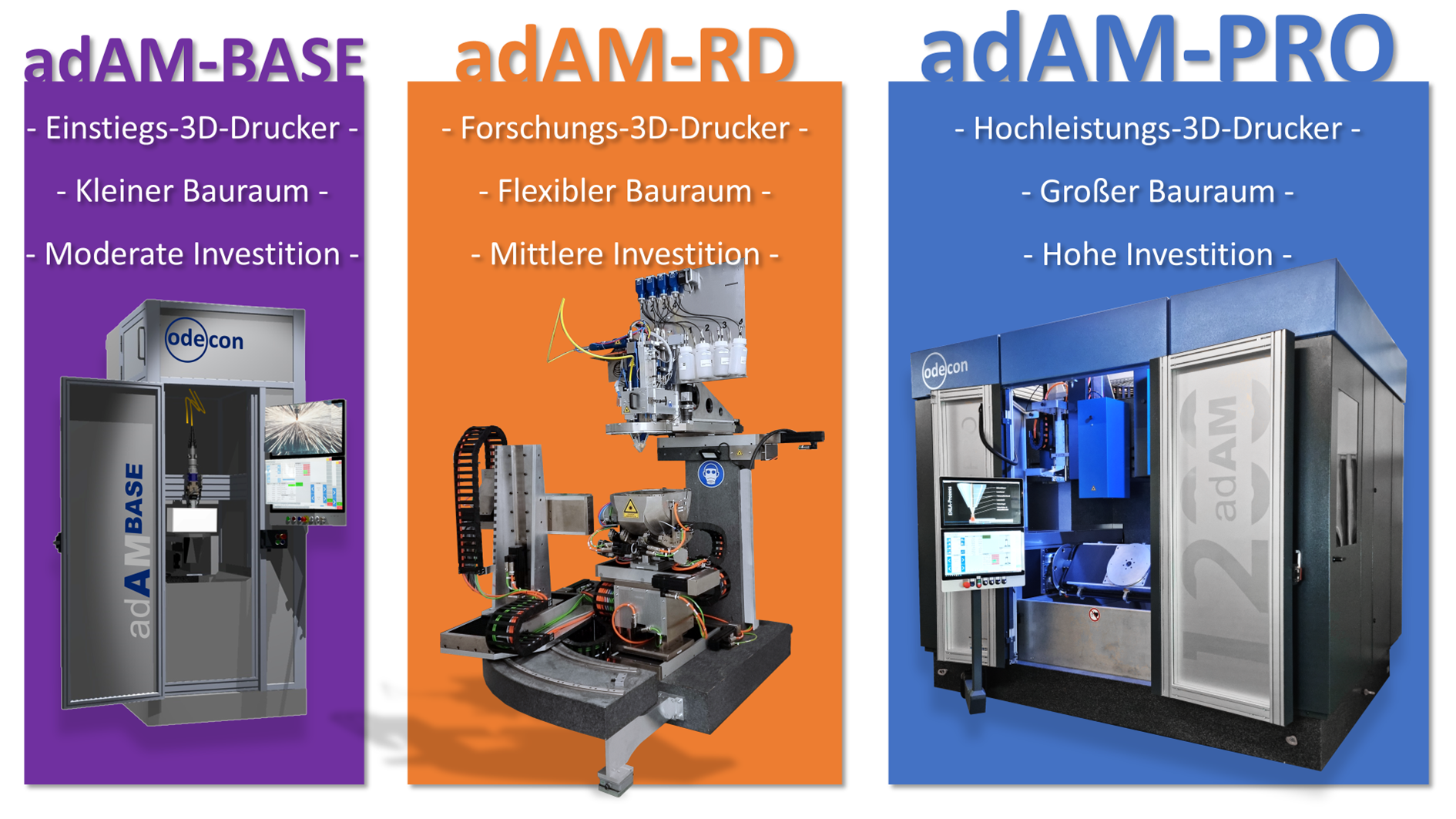

adAM-BASE®, adAM-PRO®, and adAM-RD® systems are modular and can be individually adapted to your manufacturing requirements. Whether for one-off or series production, research or development – we offer the right solution for your additive manufacturing challenges.

Discover the future of metalworking with ODeCon – your partner for innovative manufacturing technologies:

adAM-BASE®

Multifunctional 3D printer for entry into industrial series production

HIGHLIGHTS

- 5D-eLA®-Technology: Changes in materials and material properties

- isCAM - Offline railway planning software

- Hybrid manufacturing

- Additive 3D construction of contours

- 3D surface processing

- 3D coating

- Max. part size: Ø400 x 200 [mm]

- Up to 3 integrated machining heads

- Up to 6 integrated powder feed pots

- Small footprint of 1,000 x 1,100 mm²

- Glovebox / Inertizable work area (option)

Technical data

BASIC VERSION

- adAM 5-axis kinematics

- Machining heads: 1

- Build volume (X/Y/Z) 300 x 200 x 200 mm³

- Speed (X/Y/Z) 30m/min

- Acceleration (X/Y/Z) 2.3G (23 m/s²)

- Turntable diameter 230mm

- Repeatability <6µm

- Payload up to 25kg

- Clamping table heating (without)

- Clamping table speed 500 rpm

- Laser power 2,000 watts

FULLY EQUIPPED

- adAM 5 4-axis kinematics

- Machining heads: 3

- Build volume (X/Y/Z) 300 x 200 x 200 mm³

- Inerted workspace

- Speed (X/Y/Z) 150m/min

- Acceleration (X/Y/Z) 5G (50 m/s²)

- Turntable diameter 230mm

- Repeatability <2µm

- Payload up to 40 kg

- Clamping table heating 500°C

- Clamping table speed 2,400 rpm

- Laser power 8,000 watts

Applications

- 3D laser cladding (powder/wire)

- 3D/2D-Laser-Schneiden

- 3D/2D joining (soldering, welding, gluing)

- 3D surface processing

- Milling / drilling

Options

- up to 11 extension axes

- up to 3 laser tool slides

- Laser wire LMD head

- Laser cutting head

- Laser polishing head

- Milling / drilling head

- Variable installation height

- Extensive process sensors

- Increased payload up to 100kg

- Glovebox / inerted work area

adAM-RD®

Highly flexible 3D printing system for research and development tasks in the areas of processes and materials

HIGHLIGHTS

- 5D-eLA®-Technology: Changes in materials and material properties

- isCAM - Offline railway planning software

- Hybrid manufacturing

- Additive 3D construction of contours

- 3D surface processing

- 3D coating

- Max. part size Ø1,500mm x 1,500mm

- Interference contourfree Workpiece clamping plate

- Expansion to up to 16 axes

- Any number of material feeds

- 360° mounting options for sensors

- Additional axes for automatic sensor adjustment

- Clamping table heating system up to 1,000°C

- Separate laser class 1 protective housing (option)

- X-ray analysis system (option)

Technical data

BASIC VERSION

- adAM 5-axis kinematics

- Build volume (X/Y/Z) 300 x 300 x 300 mm³

- Speed (X/Y/Z) 30...150m/min

- Acceleration (X/Y/Z) up to 5G (50 m/s²)

- Build volume (X/Y/Z) 300 x 300 x 300 mm³

- Turntable diameter 250...300mm

- Repeatability <2µm

- Payload up to 200kg

- Clamping table heating max 1,000°C

- Clamping table speed 400...2,500 rpm

- Laser power 1,000...20,000 watts

Applications

- 3D laser cladding (powder/wire)

- 3D/2D-Laser-Schneiden

- 3D/2D joining (soldering, welding, gluing)

- 3D surface processing

Options

- up to 11 extension axes

- up to 5 laser tool slides

- Variable installation space size

- Extensive process sensors

- Variable safety fence system

- Increased payload up to 2,500 kg

- X-ray analysis

adAM-PRO®

High-speed 3D printing system for demanding industrial series production with world-unique performance

HIGHLIGHTS

- 5D-eLA®-Technology: Changes in materials and material properties

- isCAM - Offline railway planning software

- Hybrid manufacturing

- Additive 3D construction of contours

- 3D surface processing

- 3D coating

- Max. part size Ø1,000mm x 500mm

- High metal deposition rates >1,000cm³/h

- Up to 4 integrated machining heads

- High-speed axes up to 360 m/min

- 2 to 12 powder feed pots

- Component separation from the workpiece carrier

- Fully integrated system components (laser, extraction, etc.)

- Integrated security systems

Technical data

- adAM 5-axis kinematics

- Build volume (X/Y/Z) 600 x 450 x 450 mm³

- Axis speed up to 360m/min

- Acceleration up to 13G (130 m/s²)

- Repeatability up to 5µm

- Payload up to 80kg

- Rotating round clamping table

- Clamping table diameter 350mm

- Clamping table speed 400...2,500 rpm

- Laser power 1,000...25,000 watts

Applications

- 3D laser cladding (powder/wire)

- 3D/2D-Laser-Schneiden

- 3D/2D joining (soldering, welding, gluing)

- 3D surface processing

- Milling / drilling

Options

- up to 5 extension axes

- up to 4 laser tool slides

- Max. build volume (X/Y/Z) 1,000 x 600 x 500 mm³

- Increased payload up to 500kg

- Glove-Box-System

- Laser power up to 25,000 W

Additive manufacturing technology: Innovation meets precision

Our highlights at a glance

- Multitool processing: Reduce production times by integrating multiple processing heads for additive manufacturing, laser cutting, surface coating and polishing.

- High-performance drive technology: Achieve impressive deposition rates with axis speeds of up to 360 m/min and accelerations of up to 130 m/s².

- Hybrid additive machining: Efficiently expand existing products with additional contours, surfaces and cutouts – all in one step.

- 5D-eLA® technology: Change materials and adjust material properties during ongoing powder-based additive manufacturing.

- Ad hoc material change: Flexibility through the change of alloy components during production.

- Automated component removal: Benefit from integrated systems for automatic separation of the component from the workpiece carrier and optional robot unloading.